High-performance glass is revolutionizing everything from skyscrapers to smartphones. It’s not just another type of window; it’s a material with incredible strength, durability, and clarity, all thanks to advanced manufacturing techniques and material science. From tempered glass in your car’s windshield to laminated glass in your home, high-performance glass is everywhere. This exploration delves into its diverse applications, properties, and the fascinating science behind its impressive performance.

Different types of high-performance glass, like tempered, laminated, and coated glass, each have unique properties and are suited for various applications. This guide explores the specific strengths and weaknesses of each type, comparing them based on factors like strength, durability, and clarity. We’ll also examine the historical development of high-performance glass, the innovative manufacturing processes, and the environmental impact of its production.

Introduction to High-Performance Glass

Source: lisec.com

High-performance glass encompasses a range of specialized glass types designed for specific applications demanding superior properties beyond standard glass. These glasses are engineered to possess enhanced strength, durability, safety, and other functional characteristics, making them suitable for a wide array of industries. From architectural designs to automotive components, high-performance glass plays a crucial role in modern applications.High-performance glass is distinguished by its tailored properties.

It is not just stronger, but also safer and often more durable and resistant to environmental factors, compared to conventional glass. Different types of high-performance glass are created through specific manufacturing processes, including varying compositions, treatments, and coatings, which in turn affect their performance characteristics.

Types of High-Performance Glass

High-performance glass comes in various forms, each with its own set of advantages. Tempered glass, laminated glass, and coated glass are prominent examples. Each type is engineered for specific applications, demanding different performance characteristics.

Tempered Glass

Tempered glass, also known as safety glass, is produced by heating and rapidly cooling annealed glass. This process introduces internal stresses that significantly increase its strength and resistance to breakage compared to annealed glass. When broken, tempered glass shatters into small, relatively harmless, granular pieces, making it a popular choice in applications requiring enhanced safety. This characteristic is particularly valuable in applications like shower doors and windows where the risk of sharp shards is minimized.

Laminated Glass

Laminated glass consists of two or more sheets of glass bonded together with a thin, interlayer of polyvinyl butyral (PVB) or other polymeric material. This interlayer acts as a shock absorber, preventing the glass from shattering completely when subjected to impact. Even if the glass breaks, the interlayer holds the pieces together, reducing the risk of injury and maintaining structural integrity.

This property makes it an ideal choice for applications requiring high impact resistance, such as automotive windshields and safety glazing in high-traffic areas.

Coated Glass

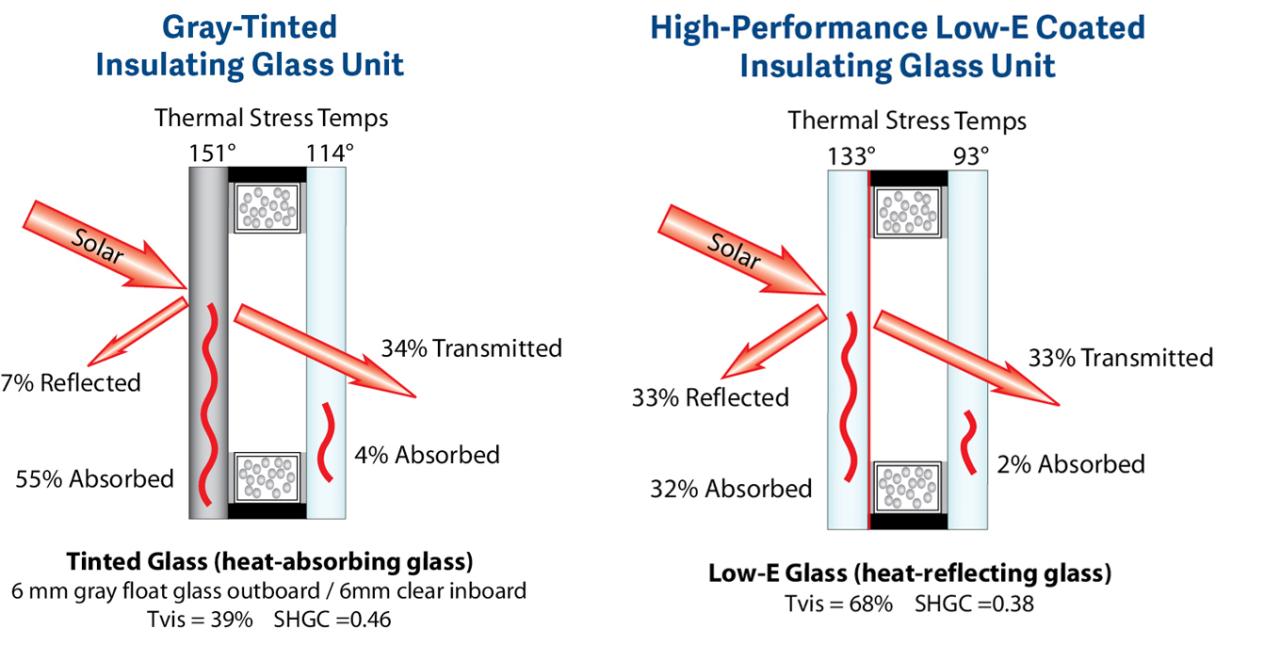

Coated glass involves applying a thin layer of a specific material to the surface of the glass. These coatings can enhance a variety of properties, such as reducing glare, improving energy efficiency, or increasing scratch resistance. For example, low-e coatings reduce the transmission of heat and ultraviolet (UV) light, enhancing energy efficiency in windows. Other coatings can improve clarity, such as anti-reflective coatings.

Material Science Behind Enhanced Properties

The enhanced properties of high-performance glass stem from the careful control of the glass’s composition and the application of specific manufacturing processes. The addition of certain elements during the manufacturing process can significantly alter the glass’s strength, durability, and other characteristics. Furthermore, surface treatments and coatings can further enhance these properties. For example, the addition of certain metallic oxides can increase the glass’s resistance to chemical attack.

Comparison of High-Performance Glass Types

| Type | Strength | Durability | Clarity |

|---|---|---|---|

| Tempered Glass | High | High | Good |

| Laminated Glass | High | Very High (impact resistance) | Good (slightly reduced due to interlayer) |

| Coated Glass | Moderate to High (depending on coating) | Moderate to High (depending on coating) | Good to Excellent (depending on coating) |

Applications of High-Performance Glass

Source: buildingmedia.com

High-performance glass, with its enhanced properties like strength, durability, and energy efficiency, is revolutionizing various industries. Its versatility allows for innovative designs and improved functionality, making it a key material in modern construction, transportation, and consumer products. This wide-ranging applicability stems from the tailored compositions and manufacturing processes that result in specialized glass types, each optimized for a specific task.

Architectural Design and Construction

High-performance glass plays a crucial role in modern architecture, enabling designers to create stunning structures while enhancing the building’s performance. Its diverse properties, such as thermal insulation, light transmission, and soundproofing, significantly impact the overall design and operational efficiency of buildings. The use of laminated glass, for example, enhances safety and security, while insulated glass units (IGUs) improve energy efficiency by reducing heat transfer.

This leads to lower energy bills and a smaller carbon footprint. Buildings incorporating high-performance glass can achieve LEED certifications, reflecting the sustainable design philosophy. Modern skyscrapers and commercial buildings often feature expansive facades crafted from high-performance glass, showcasing the structural and aesthetic possibilities of this material.

Automotive and Transportation

The automotive industry relies heavily on high-performance glass for safety and aesthetics. Laminated safety glass, specifically designed for automotive applications, offers superior impact resistance. This crucial property minimizes the risk of injury in case of accidents. In addition, advanced coatings on high-performance glass for vehicles can enhance visibility, reducing glare and improving driver safety, particularly in harsh weather conditions.

High-performance glass also contributes to fuel efficiency by improving insulation and reducing heat transfer, thus minimizing energy loss. Furthermore, the innovative design possibilities of high-performance glass enhance the aesthetic appeal of vehicles.

Electronics Industry

High-performance glass finds applications in the electronics industry, particularly in touchscreens and displays. Its exceptional clarity and scratch resistance are crucial for these applications. The ability to create ultra-thin glass substrates is key to miniaturizing electronic devices, improving their performance and efficiency. This also plays a vital role in the production of flat-panel displays. Specific types of high-performance glass are designed to withstand the high temperatures and pressures encountered during manufacturing processes.

This ensures the quality and reliability of the final product.

Consumer Products

High-performance glass is increasingly used in a variety of consumer products. Its lightweight nature and shatter resistance make it an attractive material for high-end furniture, such as tabletops and decorative elements. Furthermore, its durability and aesthetic qualities contribute to the creation of stylish and functional consumer products. High-performance glass is often used in high-end appliances, enhancing their design and safety features.

The growing use of high-performance glass in consumer products demonstrates its increasing relevance in everyday life.

Table of Applications and Types

| Application | Type of Glass | Specific Features |

|---|---|---|

| Architectural Facades | Laminated Glass, Tempered Glass, Insulated Glass Units (IGUs) | Enhanced safety, improved thermal insulation, high impact resistance, superior energy efficiency |

| Automotive Windshields | Laminated Safety Glass, Heat-resistant Glass | Exceptional impact resistance, improved visibility, enhanced safety features, reduced glare |

| Touchscreens and Displays | Low-Iron Glass, Ultra-Thin Glass | High clarity, scratch resistance, and flexibility, suitable for advanced electronic devices |

| Consumer Products (e.g., Furniture, Appliances) | Tempered Glass, Laminated Glass, Specialty Glass | Durability, aesthetic appeal, lightweight nature, and resistance to breakage |

Manufacturing Processes

High-performance glass, with its unique properties, requires specialized manufacturing techniques. These methods ensure the glass achieves the desired strength, durability, and optical clarity. Understanding these processes is crucial for appreciating the sophistication and precision involved in producing these advanced materials.The production of high-performance glass encompasses a range of complex procedures, from selecting the raw materials to controlling the intricate steps in the manufacturing process.

Different types of high-performance glass often necessitate unique techniques tailored to their specific applications.

Raw Materials

High-performance glass production relies on carefully selected raw materials. The quality and purity of these materials significantly impact the final product’s characteristics. Common raw materials include silica sand, soda ash, limestone, and various oxides, such as boron oxide, alumina, or lead oxide. The precise composition of these materials is critical in achieving the desired properties of the glass.

For example, adding boron oxide enhances the glass’s resistance to thermal shock.

Manufacturing Techniques

Several techniques are used to produce high-performance glass, each with its advantages and limitations. These methods vary depending on the desired properties and application of the glass.

Float Glass Process

This widely used method for producing flat glass is adapted for high-performance glass applications by controlling the raw material composition and refining the cooling process. The process involves melting raw materials in a furnace, then pouring the molten glass onto a bath of molten tin. The surface tension of the molten glass creates a flat surface as it floats on the tin bath.

Subsequent annealing processes control the cooling rate, preventing internal stresses and ensuring uniformity.

Float glass process is particularly suitable for large-scale production of high-performance flat glass.

Chemical Vapor Deposition (CVD)

This technique is often employed to create thin, high-quality coatings on glass substrates. In CVD, gaseous precursors are introduced into a reaction chamber, where they decompose and deposit on the glass surface, forming a thin film with enhanced properties. This method is crucial for creating anti-reflective coatings or specialized optical filters for high-performance glass.

Ion Exchange

Ion exchange alters the chemical composition of the glass surface, changing its refractive index and mechanical properties. This method is often used to produce glass with enhanced durability or specific optical characteristics.

High-performance glass is all about strength and clarity, but sometimes less is more. Modern designers are increasingly embracing minimalist glass design, focusing on clean lines and simple forms to create stunning aesthetic effects. This approach to glass design can actually enhance the performance characteristics of high-performance glass, by making it appear lighter and more refined, ultimately elevating the overall visual impact.

Minimalist glass design is a great way to showcase the beauty of high-performance glass while maintaining a sophisticated aesthetic.

Other Processes

Other manufacturing processes may include special melting techniques, like using induction furnaces, or specific annealing procedures for different types of high-performance glass. These specialized approaches allow for precise control over the final product’s characteristics, enabling it to meet stringent requirements in various applications.

Steps in High-Performance Glass Production (Example: Float Glass)

- Raw materials (silica sand, soda ash, limestone) are carefully measured and mixed to create a specific chemical composition.

- The mixture is fed into a furnace, where it melts to form molten glass at high temperatures (approximately 1500-1600°C). Careful monitoring and control of the furnace temperature and atmosphere are crucial.

- The molten glass is then poured onto a bath of molten tin. The surface tension of the glass forms a flat surface as it floats on the tin.

- The glass sheet is slowly cooled and annealed to relieve internal stresses, ensuring a smooth and uniform surface.

- The cooled glass sheet is then inspected for quality, cut to the required dimensions, and prepared for further processing or application.

Future Trends and Developments

Source: made-in-china.com

High-performance glass is constantly evolving, driven by innovations in material science and manufacturing. This evolution is shaping new applications and addressing sustainability concerns, leading to a future with even more sophisticated and versatile glass products. Emerging trends and technologies are poised to redefine the possibilities of glass in various sectors.

Emerging Trends in Material Science

Advancements in material science are crucial for developing high-performance glass with enhanced properties. Researchers are exploring novel glass compositions incorporating elements like lithium, aluminum, and boron to improve strength, thermal stability, and resistance to chemical attack. For instance, incorporating nanomaterials into the glass matrix can enhance its scratch resistance and optical clarity. This could lead to the creation of glass with superior durability and performance characteristics.

Manufacturing Process Innovations

Innovative manufacturing processes are also essential for producing high-performance glass cost-effectively. Automation and precision technologies are enabling the creation of complex shapes and intricate designs. Additive manufacturing techniques, such as 3D printing, are also being explored for producing customized glass components. This approach could revolutionize the manufacturing of high-performance glass, allowing for greater design flexibility and potentially lowering production costs.

Potential Applications of Future High-Performance Glass

The diverse range of applications for high-performance glass is likely to expand. Imagine lightweight, yet extremely strong glass for architectural applications, or transparent solar panels with improved efficiency. Advanced optical glass will likely be utilized in sophisticated telecommunication and sensing equipment. Furthermore, glass with enhanced self-cleaning properties could find applications in various sectors, from automotive to construction.

Sustainability Considerations

Sustainability is a critical factor in the development of future high-performance glass. The focus is shifting towards using recycled materials and reducing the environmental impact of manufacturing processes. Researchers are exploring alternative energy sources for the glass melting process, and developing glass with improved energy efficiency for applications like windows. The aim is to produce high-performance glass in an environmentally responsible manner, using sustainable practices.

Table of Potential Future Developments

| Trend | Description | Potential Impact |

|---|---|---|

| Enhanced Durability and Strength | New glass compositions and manufacturing techniques will result in glasses with increased resistance to scratches, impacts, and extreme temperatures. | Wider range of applications, including high-performance building materials and advanced automotive components. |

| Improved Optical Properties | Advances in glass composition will lead to glasses with enhanced clarity, color control, and other optical characteristics. | Enhanced performance in optical devices, displays, and telecommunications equipment. |

| Self-Healing Glass | The development of glass that can repair microscopic damage, potentially extending the lifespan of components. | Improved durability and reduced maintenance costs in various applications. |

| Sustainable Manufacturing Practices | Increased use of recycled materials, and environmentally friendly manufacturing processes. | Reduced environmental footprint and potential cost savings associated with material sourcing. |

Summary

Source: surepulse.com

In conclusion, high-performance glass has come a long way, offering a range of benefits for various industries. From its enhanced properties to its diverse applications, this remarkable material is shaping the future of construction, transportation, and more. While the future holds exciting advancements, the current state of high-performance glass already showcases its impressive potential and impact on our lives.

Q&A: High-performance Glass

What are the different types of high-performance glass?

Common types include tempered glass (for strength), laminated glass (for safety), and coated glass (for improved clarity or other features). Each has unique characteristics.

How is high-performance glass different from regular glass?

High-performance glass is treated or made with different materials to enhance its strength, durability, and other desired properties compared to standard glass.

What are some specific applications of high-performance glass?

High-performance glass is used in architectural designs, automotive windshields, electronics, and various consumer products, showcasing its versatility.

What are the environmental impacts of high-performance glass production?

The environmental impact varies depending on the specific manufacturing process. Some methods are more sustainable than others, and this is an area of ongoing research and development.

- High-performance glass A detailed look - February 15, 2026

- Coastal Modern House A Guide - February 13, 2026

- Floral Centerpieces A Complete Guide - February 11, 2026