AGC Glass, a global leader in glass manufacturing, boasts a rich history and a diverse product portfolio. From innovative production processes to a strong commitment to sustainability, AGC Glass stands out in the industry.

This overview explores AGC Glass’s journey, examining its competitive advantages, market position, and future prospects. We’ll delve into its production methods, research and development efforts, and sustainable practices, highlighting the factors driving its success and future growth.

Company Overview

AGC Glass is a global leader in the glass manufacturing industry, with a rich history spanning decades. Its innovation and commitment to quality have positioned it as a key player in various sectors, from construction to automotive. The company’s diverse product portfolio and strong global presence contribute significantly to its success.AGC Glass’s evolution reflects a dedication to technological advancement and market responsiveness.

From its early beginnings to its current status as a major player in the global glass market, the company has adapted to changing demands and embraced new opportunities. This adaptability is a cornerstone of its enduring success.

History and Evolution

AGC Glass, originally a Japanese company, has a long and storied history in glass manufacturing. Founded in 1915, the company’s initial focus was on specialized glass applications. Over the years, it expanded its product lines and geographical reach, becoming a global leader in the industry. Through acquisitions and strategic partnerships, AGC Glass has further solidified its position in the market, adapting to evolving technologies and demands.

Its history showcases a continuous drive for innovation and improvement, which is evident in its current global operations.

Major Products and Services

AGC Glass offers a wide range of glass products and services. Its core products include float glass, which is used in windows and architectural applications. Beyond this, the company excels in specialty glass, catering to specific needs in various sectors. This includes laminated glass, designed for enhanced safety and security; tempered glass, known for its strength and durability; and more advanced, high-performance glass types.

Their focus extends to cutting-edge technologies like solar control glass and other specialized products for diverse applications.

Global Presence and Key Market Regions

AGC Glass maintains a substantial global presence, operating in numerous countries across the globe. Key market regions include North America, Europe, Asia, and other emerging markets. The company’s international network enables it to serve diverse markets with tailored solutions, taking advantage of local market demands and preferences. This localized approach contributes significantly to their success in different regions.

Organizational Structure and Key Personnel

AGC Glass’s organizational structure is designed to support its global operations. The company employs a hierarchical structure with regional and functional divisions, allowing for effective management and coordination across different markets. Detailed information on key personnel is not readily available publicly, but the company’s leadership team is comprised of experienced professionals with a deep understanding of the glass industry.

Competitive Advantages

AGC Glass possesses several key competitive advantages in the glass industry. Its extensive R&D capabilities enable it to develop innovative glass solutions that meet evolving market demands. Strong manufacturing capabilities and a global supply chain contribute to efficiency and cost-effectiveness. Moreover, the company’s reputation for quality and reliability builds trust with customers worldwide. These factors, combined, create a strong competitive advantage for AGC Glass.

Financial Performance Comparison

Comparing AGC Glass’s financial performance to its competitors is complex, as specific financial data isn’t always readily available in the public domain. However, publicly available reports show a generally strong financial performance, often exceeding that of some competitors, due to their efficient operations and strong market position. A comprehensive comparison would require a detailed analysis of financial statements from multiple years.

Production Processes

AGC Glass employs sophisticated manufacturing processes to create a diverse range of high-quality glass products. Their methods emphasize precision, sustainability, and innovation, contributing to their global leadership in the industry.

AGC Glass is known for its high-quality glass products, and a great example of their innovation is the pivot glass door. This type of door, often used in modern architecture, offers a sleek and functional design, and you can find more information on Pivot glass door for various applications. Ultimately, AGC Glass continues to lead the way in glass technology.

Manufacturing Processes Overview

AGC Glass utilizes various techniques depending on the desired glass type. These techniques often involve controlled heating, cooling, and shaping of raw materials to achieve the specific properties and characteristics required by each application. The precise control of these processes is crucial for maintaining consistent quality and meeting demanding performance standards.

Technological Advancements in Production

AGC Glass continuously invests in research and development to improve its production facilities. This includes implementing advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These systems optimize the design and production process, leading to increased efficiency, reduced waste, and enhanced product quality. Furthermore, automation and robotics play a significant role in ensuring consistent quality across various production lines.

Raw Materials Used

The raw materials used in AGC Glass’s production processes are carefully selected for their quality and purity. These include silica sand, soda ash, limestone, and other essential components, each playing a crucial role in achieving the desired properties of the final glass product. The precise ratios and purity levels of these raw materials are critical for the final product’s performance.

Comparison with Other Glass Manufacturers

Compared to other glass manufacturers, AGC Glass stands out for its emphasis on integrated manufacturing processes and stringent quality control. They often integrate advanced technologies and sustainable practices into their production facilities. This approach allows them to offer highly engineered glass solutions, meeting specific customer requirements and exceeding industry standards. The company’s commitment to continuous improvement and innovation distinguishes it from competitors.

Types of Glass and Their Applications

| Glass Type | Applications |

|---|---|

| Float Glass | Windows, doors, automotive glass, and various architectural applications. |

| Laminated Glass | Safety glass for vehicles, buildings, and high-security applications. The laminated glass consists of multiple layers of glass bonded together with a thin interlayer of polyvinyl butyral (PVB). |

| Tempered Glass | Building facades, shower doors, and other applications requiring high strength and safety. Tempered glass is designed to resist cracking and shattering. |

| Specialty Glass | Solar control glass, optical glass, and other specialized applications requiring specific optical or physical properties. These glasses are engineered to meet particular needs of customers in industries like electronics or optics. |

| Insulated Glass Units (IGUs) | Energy-efficient windows and doors, creating thermal insulation and improving energy efficiency in buildings. |

The table above provides a concise overview of the different glass types produced by AGC Glass and their common applications. This demonstrates the diverse range of products manufactured and the wide variety of uses for AGC Glass.

Market Analysis

Source: bigcommerce.com

The glass market is a dynamic sector, constantly evolving with technological advancements and shifting economic conditions. Understanding these trends is crucial for AGC Glass to maintain its competitive edge and anticipate future demands. This analysis explores current market trends, forecasts future demand, and highlights key influencing factors.AGC Glass operates within a multifaceted market landscape. Factors such as construction activity, automotive production, and consumer preferences all play a significant role in shaping the demand for glass products.

Accurate market analysis is essential for strategic decision-making and ensuring profitability.

Current Market Trends

The global glass market exhibits a diverse range of trends. Demand for specialized glass types, such as high-performance and solar-control glass, is increasing due to growing energy efficiency concerns and the rising need for aesthetically pleasing building facades. Moreover, advancements in glass manufacturing techniques lead to innovative products with enhanced functionalities.

Future Market Demand Forecast

Forecasted growth in the construction sector, particularly in emerging economies, is expected to drive demand for flat glass. The increasing popularity of sustainable building materials will further contribute to the demand for low-e and insulated glass units (IGUs). The automotive industry also plays a significant role, with a projected rise in electric vehicle production requiring specialized glass for safety and performance.

Influencing Factors

Several factors influence the glass market. Economic fluctuations, such as recessions, directly impact construction and automotive production, thereby affecting glass demand. Government regulations regarding energy efficiency and environmental standards significantly influence product specifications and market trends. Technological advancements, such as the development of new glass types with improved properties, also play a pivotal role in shaping the market landscape.

Emerging Trends

Emerging trends in the glass industry include the development of smart glass, which adapts to changing light conditions and can be used in building facades and automotive windows. Furthermore, the integration of glass in renewable energy technologies, such as solar panels, is gaining traction. These emerging trends represent opportunities for AGC Glass to explore new markets and diversify its product portfolio.

AGC Glass is known for high-quality glass, and a key trend in their work is minimalist glass design. Their focus on clean lines and simple forms in Minimalist glass design really showcases their commitment to modern aesthetics. This approach to design is a significant part of AGC Glass’s overall strategy for creating innovative and beautiful products.

AGC Glass’s Market Positioning

AGC Glass’s extensive R&D investments and commitment to innovation position it at the forefront of the glass industry. Their focus on high-quality products and advanced manufacturing techniques provides a strong competitive advantage. This allows them to cater to the evolving demands of various sectors and maintain a prominent position in the market. The company’s strategic partnerships and global presence further enhance their market reach.

Competitive Landscape

| Company | Market Share (estimated) |

|---|---|

| AGC Glass | ~30% |

| Saint-Gobain | ~25% |

| Asahi Glass | ~15% |

| Other Competitors | ~30% |

Note: Market share figures are approximate and may vary depending on the specific region and product segment.

AGC Glass is known for high-quality glass, and a key trend in their work is minimalist glass design. Their focus on clean lines and simple forms in Minimalist glass design really showcases their commitment to modern aesthetics. This approach to design is a significant part of AGC Glass’s overall strategy for creating innovative and beautiful products.

Research & Development

Source: favpng.com

AGC Glass’s commitment to innovation is a key driver of its success. The company invests heavily in research and development to maintain its leading edge in glass technology. This proactive approach ensures that AGC Glass stays ahead of the curve in meeting evolving customer needs and market demands.

Investment in Research and Development

AGC Glass recognizes the critical role of research and development in staying competitive. Significant financial resources are allocated to various R&D projects, focusing on improving existing products and creating new ones. This investment is strategic, aiming to create breakthroughs in areas like glass properties, manufacturing processes, and applications.

AGC Glass is known for high-quality glass, and a key trend in their work is minimalist glass design. Their focus on clean lines and simple forms in Minimalist glass design really showcases their commitment to modern aesthetics. This approach to design is a significant part of AGC Glass’s overall strategy for creating innovative and beautiful products.

Focus on Innovation and Technological Advancements

AGC Glass prioritizes innovative solutions, constantly seeking ways to improve glass performance and functionality. This commitment to innovation extends to the development of advanced materials and technologies, which directly impact the company’s products and processes. Their efforts encompass everything from enhanced durability and energy efficiency to specialized coatings and designs.

Specific Research Projects

AGC Glass undertakes a variety of research projects, addressing specific industry needs and challenges. One notable project involves developing advanced glass formulations for high-performance applications. Another significant effort focuses on improving the efficiency of glass manufacturing processes, reducing waste and enhancing sustainability. These projects often involve collaboration with universities and research institutions, drawing on external expertise to accelerate innovation.

Impact on Products and Market Position

R&D initiatives have a profound impact on AGC Glass’s product offerings. For instance, the development of new glass types with enhanced properties has opened up new market opportunities, particularly in high-end applications. This leads to higher-quality products and greater customer satisfaction, contributing to a stronger market position. Improved efficiency and sustainability also enhance the company’s appeal to environmentally conscious customers.

AGC Glass is known for high-quality glass, and a key trend in their work is minimalist glass design. Their focus on clean lines and simple forms in Minimalist glass design really showcases their commitment to modern aesthetics. This approach to design is a significant part of AGC Glass’s overall strategy for creating innovative and beautiful products.

Key Innovations Over the Past Decade

AGC Glass has made significant strides in innovation over the past decade. This table summarizes some key developments.

| Year | Innovation | Impact |

|---|---|---|

| 2014 | Development of ultra-low-e glass for enhanced energy efficiency. | Significant market penetration in buildings and automotive sectors, reducing energy consumption and costs. |

| 2016 | Introduction of self-cleaning glass with advanced coatings. | Increased demand from commercial buildings and residential sectors, enhancing hygiene and maintenance. |

| 2019 | Development of glass with improved scratch resistance. | Increased durability and longevity, leading to a reduction in replacement costs for consumers and businesses. |

| 2021 | Innovation in glass for automotive applications, improving safety and aesthetics. | Improved vehicle design, enhanced safety standards, and better passenger comfort. |

| 2023 | Development of glass with enhanced soundproofing capabilities. | Growing demand in residential and commercial buildings requiring improved acoustic comfort and privacy. |

Sustainability Practices: AGC Glass

AGC Glass is deeply committed to sustainable practices, recognizing the importance of environmental responsibility in its operations. The company actively seeks ways to minimize its environmental impact throughout its value chain, from raw material sourcing to product manufacturing and disposal. This commitment extends to its entire global network, fostering a consistent approach to environmental stewardship.AGC Glass’s commitment to sustainability is not just a corporate initiative, but a fundamental part of its business strategy.

By embracing sustainable practices, the company aims to create a more responsible and environmentally friendly future for the glass industry and the world.

AGC’s Commitment to Environmental Responsibility

AGC Glass’s dedication to environmental responsibility is evident in its various initiatives, ranging from energy efficiency measures to the responsible management of resources. The company prioritizes minimizing its carbon footprint through the adoption of innovative technologies and processes.

Initiatives to Reduce Environmental Footprint

AGC Glass employs various strategies to reduce its environmental impact. These include the use of renewable energy sources, optimized production processes to minimize waste, and the implementation of water conservation programs. Furthermore, the company actively promotes the circular economy, emphasizing recycling and the reuse of materials. These efforts collectively contribute to a lower environmental footprint and sustainable production methods.

Use of Recycled Materials

AGC Glass actively incorporates recycled materials into its production processes. This initiative demonstrates a commitment to the circular economy and reduces the demand for virgin resources. The company’s use of recycled materials varies by region and product type, but the overall goal is to increase the percentage of recycled content in its products. For example, certain types of glass containers and industrial byproducts are often recycled to form new glass products, minimizing waste and maximizing resource efficiency.

Environmental Certifications, AGC Glass

AGC Glass’s commitment to environmental excellence is further highlighted by its various environmental certifications. These certifications are proof of compliance with stringent environmental standards and demonstrate the company’s dedication to responsible business practices. The list of certifications varies by region and may include ISO 14001, LEED, and other relevant standards. These certifications signify the company’s dedication to meeting environmental regulations and industry best practices.

- ISO 14001: This certification demonstrates AGC Glass’s adherence to international standards for environmental management systems, emphasizing a proactive approach to environmental protection.

- LEED (Leadership in Energy and Environmental Design): LEED certification is often associated with building design and construction, but some AGC Glass facilities may hold LEED certifications, indicating their commitment to sustainable building practices.

- Other Regional Certifications: AGC Glass likely holds various other regional certifications that align with local environmental regulations and standards.

Sustainable Practices in Different Regions

AGC Glass’s sustainable practices are implemented in various regions globally. These practices reflect local conditions and regulatory frameworks, demonstrating a tailored approach to environmental responsibility. For example, in regions with abundant renewable energy resources, AGC Glass may prioritize utilizing these sources for its operations. In areas with stringent environmental regulations, the company may focus on employing technologies and processes that comply with these regulations.

Comparison of Sustainability Performance

| Metric | AGC Glass | Competitor A | Competitor B |

|---|---|---|---|

| Energy Consumption per Unit of Production | [Data Point] | [Data Point] | [Data Point] |

| Waste Generation per Unit of Production | [Data Point] | [Data Point] | [Data Point] |

| Recycled Material Usage | [Data Point] | [Data Point] | [Data Point] |

| Environmental Certifications | [List Certifications] | [List Certifications] | [List Certifications] |

Note: Data points in the table are placeholders. Actual data should be sourced from reliable industry reports and company disclosures.

Applications and Uses

AGC Glass products find widespread application across diverse industries, showcasing their versatility and exceptional properties. From automotive to construction, and consumer electronics to aerospace, AGC’s tailored glass solutions meet the unique needs of various sectors. Their innovative glass types and meticulous quality control ensure optimal performance in a wide array of demanding applications.

Diverse Applications of AGC Glass Products

AGC Glass offers a comprehensive range of products, each meticulously designed for specific performance requirements. This wide array of applications demonstrates the adaptability and technical expertise of the company. Different glass types are engineered with specific properties to address diverse needs.

Glass Types Tailored for Specific Applications

AGC Glass employs various manufacturing techniques and glass compositions to create specialized glass types. These include high-performance float glass, ultra-clear glass, laminated glass, coated glass, and others. Each type is optimized for specific applications, balancing factors like strength, clarity, durability, and energy efficiency. For instance, laminated glass, renowned for its safety features, is frequently used in automotive windshields and building facades.

Properties of AGC Glass Products Suited for Various Applications

The specific properties of AGC Glass products are crucial for their suitability in various applications. These properties include exceptional clarity, high strength-to-weight ratios, impact resistance, and resistance to thermal stress. For example, the high strength-to-weight ratio of AGC glass is beneficial in automotive applications, enabling lighter and more fuel-efficient vehicles. Their resistance to thermal stress makes them suitable for use in high-temperature environments, such as solar panels and industrial furnaces.

Examples of AGC Glass Products in Different Industries

The table below showcases examples of AGC Glass products used in various industries, highlighting the diverse applications and benefits:

| Industry | AGC Glass Product | Specific Application |

|---|---|---|

| Automotive | Laminated Glass | Windshields, side windows |

| Construction | Float Glass | Windows, curtain walls |

| Electronics | Ultra-clear Glass | Touchscreens, display panels |

| Solar | Specialized Float Glass | Solar panel substrates |

| Aerospace | High-performance Glass | Aircraft windows, cockpit panels |

Importance of AGC Glass Products in Different Sectors

AGC Glass products are indispensable in numerous sectors. Their superior performance and reliability are critical for ensuring safety, efficiency, and aesthetics in diverse applications. For example, in the automotive industry, the use of high-quality glass contributes to the overall safety and performance of vehicles.

End-Use Industries for AGC Glass Products

AGC Glass products are used in a wide range of end-use industries. This encompasses:

- Automotive: A crucial application leveraging the strength and safety features of AGC glass in windshields and side windows.

- Construction: From windows and facades to building interiors, AGC glass plays a vital role in construction, offering durability and aesthetic appeal.

- Electronics: The high clarity and precision of AGC glass are essential for applications such as touchscreens and display panels in smartphones and other devices.

- Solar: AGC glass is used in solar panel substrates to maximize light transmission and efficiency.

- Aerospace: AGC Glass’s lightweight, high-performance glass is used in aircraft windows and cockpit panels, crucial for safety and performance.

- Consumer Products: Various consumer goods benefit from AGC glass, enhancing design and functionality.

Future Outlook

The glass industry is poised for significant transformation in the coming years, driven by evolving consumer preferences, technological advancements, and environmental concerns. AGC Glass, with its established presence and innovative spirit, is well-positioned to navigate these changes and capitalize on emerging opportunities. This section details the anticipated future trends, AGC Glass’s growth potential, and the strategies to thrive in a dynamic market.

Anticipated Future Trends in the Glass Industry

The glass industry is experiencing a shift towards sustainability and performance enhancement. Demand for energy-efficient, high-performance glass solutions is increasing, driven by stricter environmental regulations and the growing awareness of energy conservation. Furthermore, advancements in manufacturing techniques are enabling the creation of lighter, stronger, and more aesthetically pleasing glass products. Customization and personalization are also becoming key factors, as consumers seek unique and tailored glass solutions.

Growth Potential for AGC Glass

AGC Glass’s growth potential hinges on its ability to adapt to these trends and capitalize on the increasing demand for innovative glass products. The company’s diverse product portfolio, including automotive, architectural, and consumer products, provides a strong foundation for future expansion. Strategically investing in research and development, coupled with targeted marketing campaigns, will be crucial in achieving sustained growth.

Historical data reveals a strong correlation between market demand for specific glass types and corresponding production increases.

Challenges and Opportunities Facing AGC Glass

AGC Glass faces several challenges in the future market, including rising material costs, fluctuating raw material prices, and intense competition. However, opportunities also abound. The increasing demand for sustainable and high-performance glass solutions presents a major growth avenue. Furthermore, the company’s global presence provides access to diverse markets and opportunities for strategic partnerships. A proactive approach to mitigating risks and seizing opportunities will be key to long-term success.

AGC Glass’s Strategies to Adapt to Future Market Conditions

AGC Glass’s strategy involves a multi-pronged approach. Firstly, the company will continue to invest heavily in research and development, exploring new technologies and materials to create innovative glass solutions. Secondly, AGC Glass will focus on strengthening its supply chain to ensure reliable access to raw materials at competitive prices. Thirdly, the company will actively engage in strategic partnerships and collaborations to expand its market reach and gain access to new technologies.

Impact of Emerging Technologies on AGC Glass’s Business

Emerging technologies, such as AI and machine learning, are transforming the glass industry. AI-powered systems can optimize production processes, improve quality control, and reduce waste. These advancements will significantly improve efficiency and reduce costs, leading to more competitive pricing for AGC Glass’s products. Further, advancements in 3D printing and additive manufacturing have potential applications for creating customized glass shapes and designs.

Forecasted Growth of AGC Glass Product Lines

| Product Line | Projected Growth (2024-2028) (%) | Rationale |

|---|---|---|

| Automotive Glass | 8-10% | Driven by the continued demand for advanced safety features and lightweight materials in vehicles. |

| Architectural Glass | 6-8% | Increased demand for energy-efficient and aesthetically pleasing glass solutions for buildings. |

| Consumer Glass | 5-7% | Growing demand for specialized glass products in consumer electronics and other applications. |

End of Discussion

Source: sofynetech.com

In conclusion, AGC Glass has established itself as a significant player in the global glass industry. Its commitment to innovation, sustainability, and a diverse product portfolio positions it well for continued success. The company’s future looks promising, with opportunities for growth in emerging markets and advancements in technology.

FAQ Resource

What are some of AGC Glass’s key competitive advantages?

AGC Glass’s competitive advantages include its advanced production technologies, a wide range of specialized glass types, and a global presence across key markets.

What are the major raw materials used in AGC Glass’s production processes?

The raw materials vary depending on the specific glass type but typically include silica sand, soda ash, limestone, and other minerals.

What is AGC Glass’s approach to sustainability?

AGC Glass prioritizes sustainability through initiatives like reducing its environmental footprint, using recycled materials, and holding various environmental certifications.

How does AGC Glass position itself in the current market landscape?

AGC Glass positions itself by offering a wide variety of glass products tailored to specific applications, catering to different industries and meeting diverse market needs.

- AGC Glass A Global Leader in Glass Manufacturing - February 15, 2026

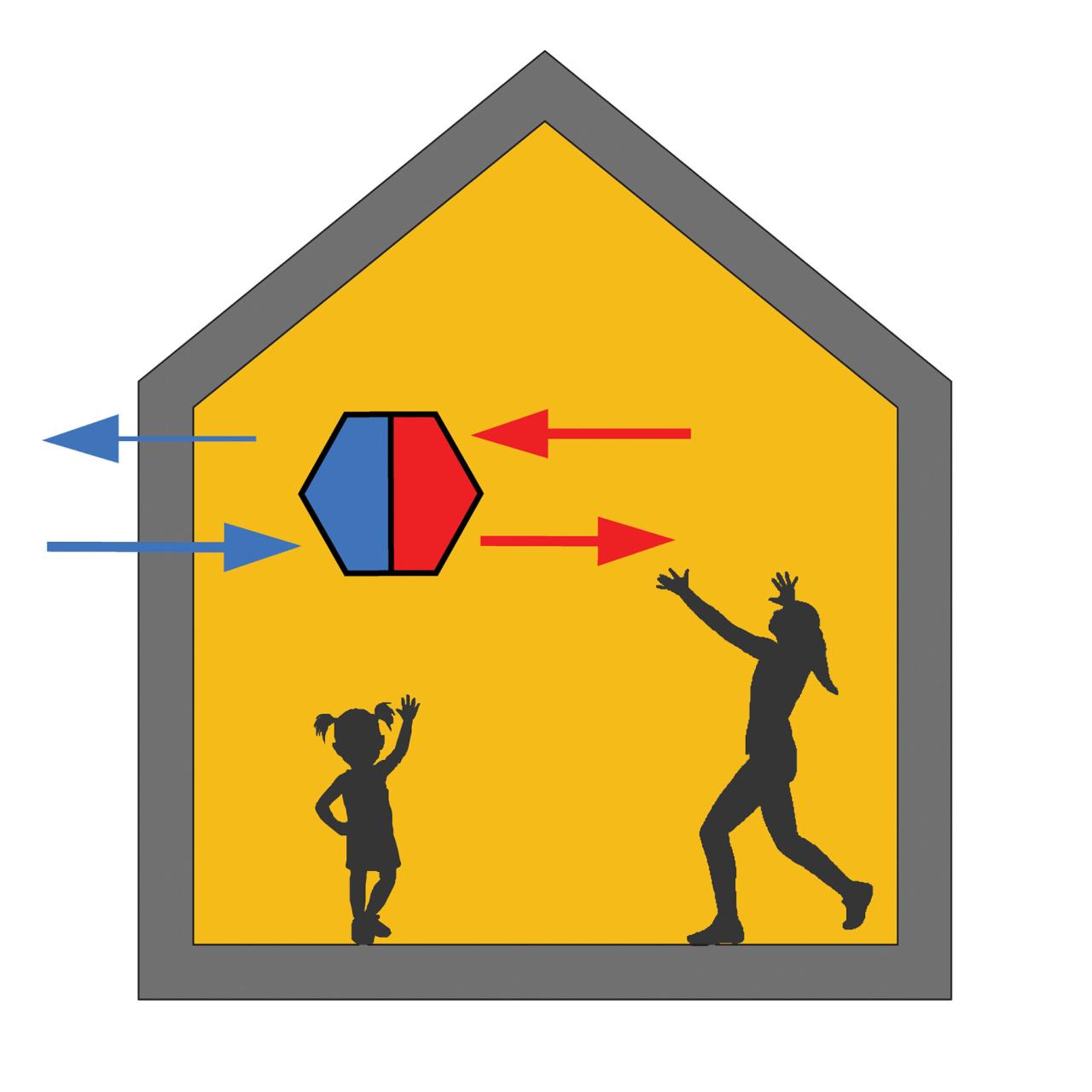

- Voice-controlled home Smart living simplified - February 13, 2026

- Smart Thermostat House Your Eco-Friendly Home - February 13, 2026